Petrochemical

Petrochemicals (sometimes abbreviated as petchems) are the chemical products obtained from petroleum by refining. Some chemical compounds made from petroleum are also obtained from other fossil fuels, such as coal or natural gas, or renewable sources such as maize, palm fruit or sugar cane.

Pet coke

Petroleum coke, abbreviated coke or petcoke, is a final carbon-rich solid material that derives from oil refining, and is one type of the group of fuels referred to as cokes.

Pet coke is the solid carbon byproduct of cracking units such as the the FCC and coker unit. In an FCC, coke forms on the catalyst and is burned off as fuel for the FCC process, resulting in no net production of coke as a product. … Refiners separate the coke from the other coker products and sell it as a product.

TAR

Tar is a dark brown or black viscous liquid of hydrocarbons and free carbon, obtained from a wide variety of organic materials through destructive distillation. Tar can be produced from coal, wood, petroleum, or peat. Mineral products resembling tar can be produced from fossil hydrocarbons, such as petroleum.

Automotive & industrial lubricants

A lubricant is generally a fluidic material with the primary function of reducing friction between surfaces in contact. … For Example: Engine oil is a specific type of lubricant that is developed for application in engines.

Industrial lubricants are oils, fluids, greases, and other compounds that reduce friction, binding, wear, or exclude moisture. Their primary function is to displace solid surfaces with a fluid film. They are otherwise used to modify surface properties, regulate temperature, or remove debris.

Marine Lubricants

Marine lubrication includes the use of ancillary grades such as hydraulic oils, compressor oils, gear oils, grease, etc. … In addition, the ship operator fre- quently requires advice on lubrication and related problems, together with a used oil analysis service

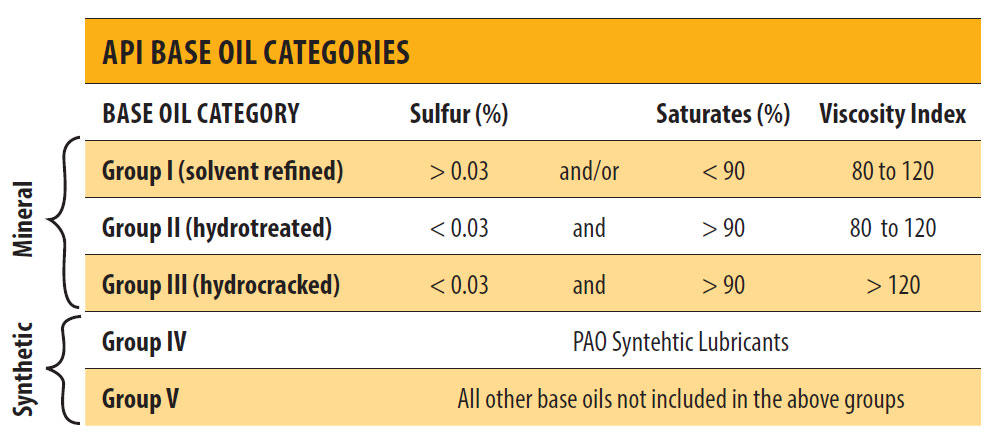

Base oils, greases and fluids

Base oils are used to manufacture products including lubricating greases, motor oil and metal processing fluids. … Base oil is produced by means of refining crude oil. This means that crude oil is heated in order that various distillates can be separated from one another.